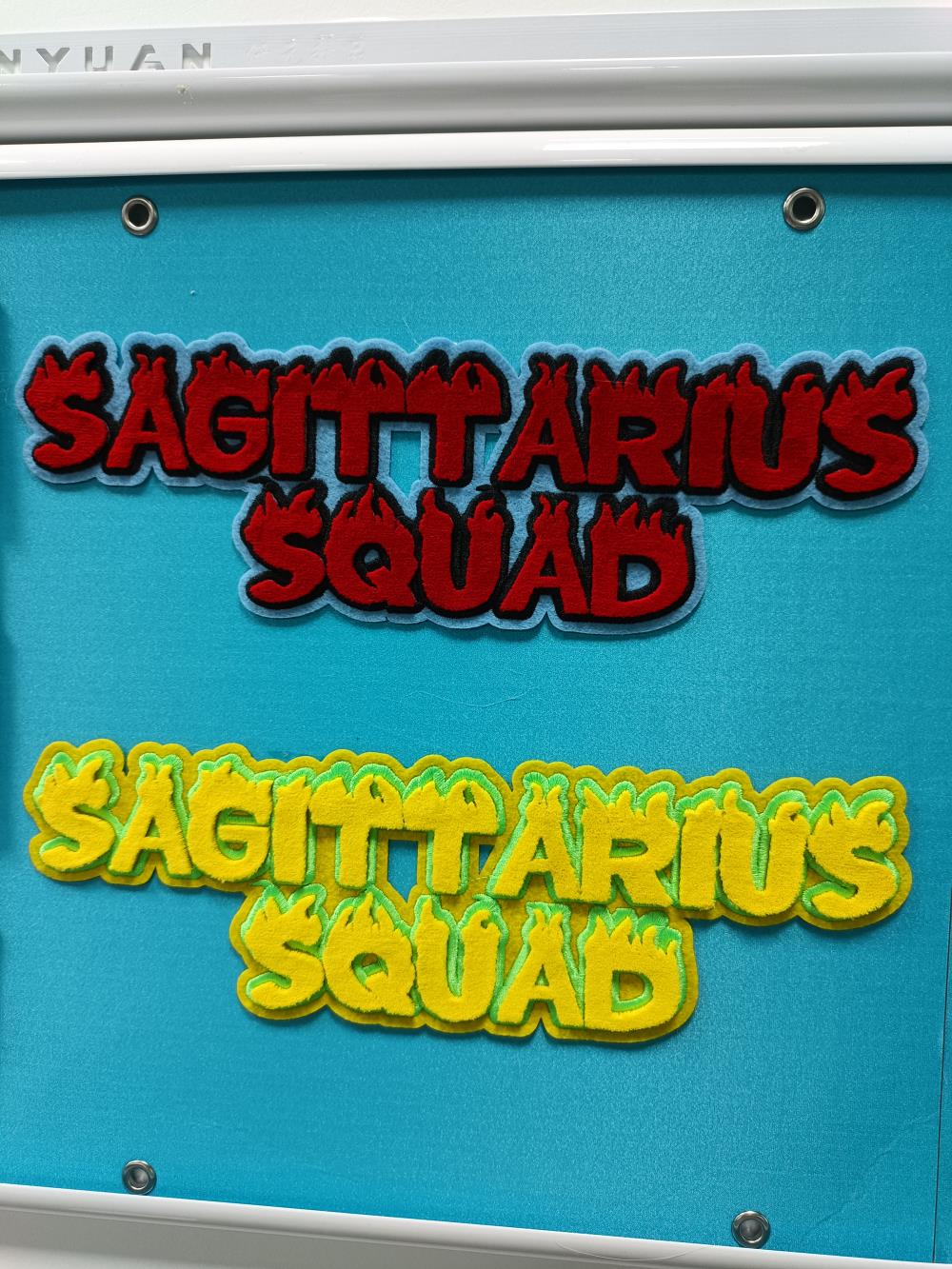

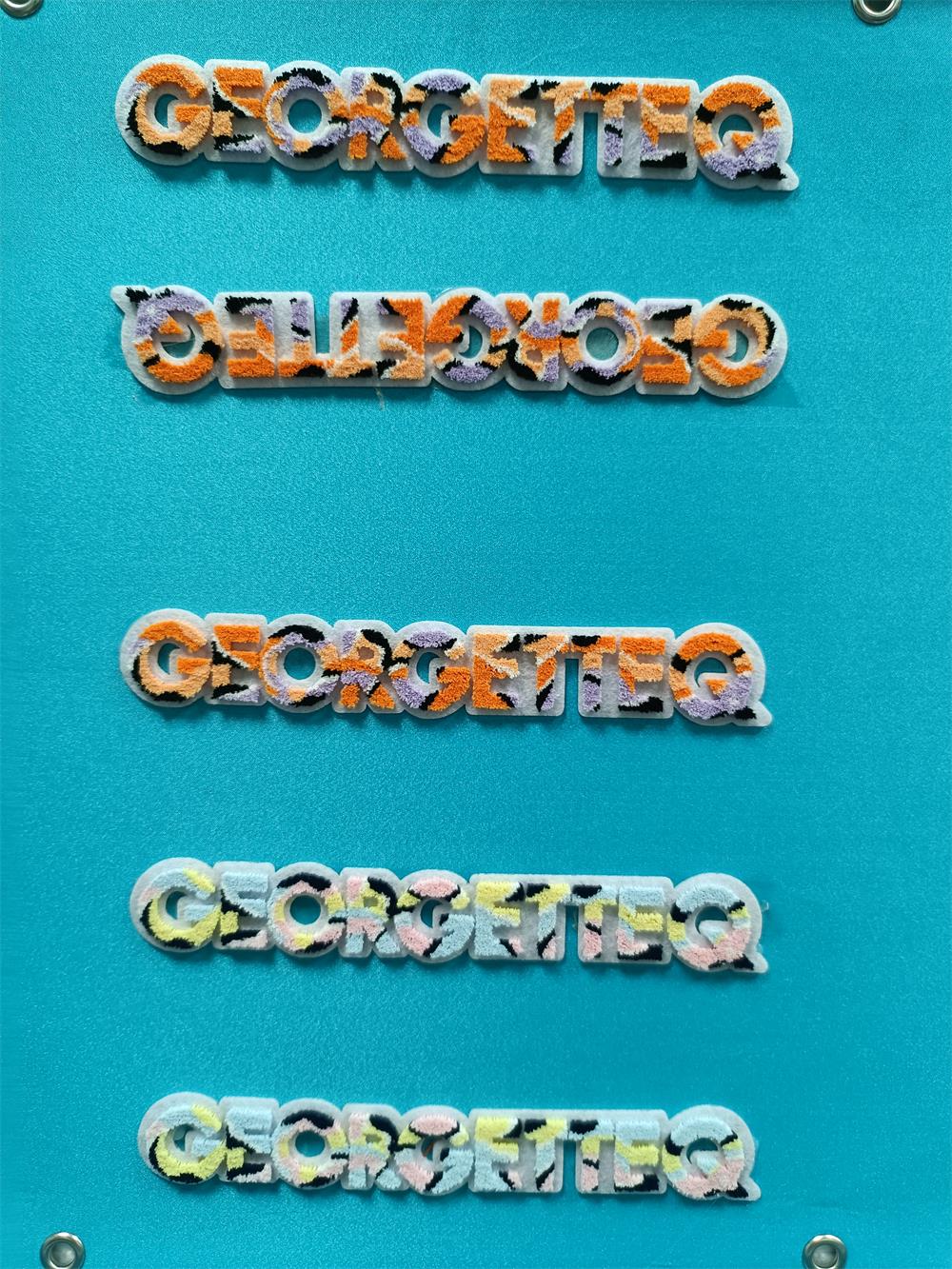

Toothbrush embroidery: is a new type of embroidery, used in clothing, home accessories, handicrafts and other fields.

English name: Toothbrush Embroidery

Features: The embroidery thread stands up like the bristles of a toothbrush

Application: clothing, home accessories, handicrafts, etc

Type: New embroidery

Principle: In the ordinary embroidery process, add a certain height of accessories (such as EVA) to the fabric, and after the embroidery is completed, use a tool to repair the embroidery thread on the EVA and remove the accessories, which forms the embroidery of the same shape as my toothbrush. Commonly known as toothbrush embroidery. Toothbrush embroidery and flocking embroidery are two different concepts, and the embroidery thread of toothbrush embroidery focuses on standing up like the hairs of a toothbrush. Flocking embroidery is an embroidery formed by pulling out the flannel wool, and the hair is down.

Method/Procedure:

According to the size of the pattern, use the opening band to open a single line on the sand net.

Cut off the sand net along the outer frame of the single line, and paste double-sided adhesive along the perimeter of the cut hole for three-dimensional glue.

According to the size of the fabric, add a circle of double-sided tape for the cloth.

Put a layer of sand net before applying the three-dimensional glue to prevent the embroidery thread from falling into the three-dimensional glue during embroidery.

The three-dimensional adhesive is attached to the double-sided adhesive, and a layer of wax paper can also be added to the three-dimensional adhesive in order to facilitate embroidery.

Apply the cloth to the double-sided tape with the reverse side up.

Put a layer of ironing on the embroidery area, and then carry out the embroidery.

After the embroidery is completed, use iron and other tools to make the iron hot melt and dip on the embroidery thread to prevent the embroidery thread from loosening after processing, or you can use ironing to prevent the embroidery thread from loosening after processing.

The ironed embroidery products are reversed for processing, and the toothbrush embroidery effect can be obtained by cutting off a layer of sand net on the surface and then taking away the three-dimensional glue, and mass production uses a toothbrush embroidery special sheet skin machine for processing.

Sheet skin machine for processing: after processing toothbrush embroidery, the peeling thickness of the sheet skin machine can be adjusted according to requirements, and the usual peeling range of the machine: 0.6~8mm.

Post time: Jul-10-2023